Bridging the Generation Gap in Critical Infrastructure Technology.

When a century-old electrical testing company met the smartphone generation, and transformed power grid maintenance forever.

Modernising the UI for Doble Spark

Client Q&A with Phil Boreham

The Doble Spark Journey

From legacy industrial interface to modern workforce-ready platform

Doble Engineering faced a crisis that threatens many traditional industries: their world-class diagnostic equipment was becoming a barrier to hiring young engineers. The same sophisticated tools that kept the world's lights on were driving away the talent needed to maintain them in the future.

The challenge wasn't just aesthetic—it was existential. How do you modernise critical infrastructure software without compromising the reliability that veteran engineers depend on, whilst making it intuitive enough for engineers who grew up with smartphones?

Bridging the generational divide

"Our industry is full of very knowledgeable and experienced engineers who learned their craft way before web apps and smartphones became the norm. They are quite happy to interact with their instruments the hard way!

However, the more recent entrants to the workplace find that way of working unacceptable. We needed to move on and provide them with a more contemporary user experience."

User experience above all

"We were looking for someone to partner with who puts UX first, regardless of the underlying technology and function of the product.

We wanted someone who could really understand the expectations of the typical user. To provide an interface to a complex technical instrument in the most user-friendly way."

Getting internal buy-in for change

“Initially there was internal resistance in our organisation. The argument was 'How can someone work with us if they don’t fully understand what our product does?' It was a hard sell.

Describing the technical workflow to someone not at all familiar with the purpose of the instrument was definitely a challenge. But it made us better at explaining what we do to an audience unfamiliar with the depths of our world of power system diagnostics.”

Key goals and outcomes

Primary Objectives:

- Create intuitive interfaces that reduce training time for new engineers

- Maintain full functionality and trust of experienced field engineers

- Enable reliable field data collection in challenging industrial environments

- Future—proof the platform for continued workforce evolution

Delivered Results:

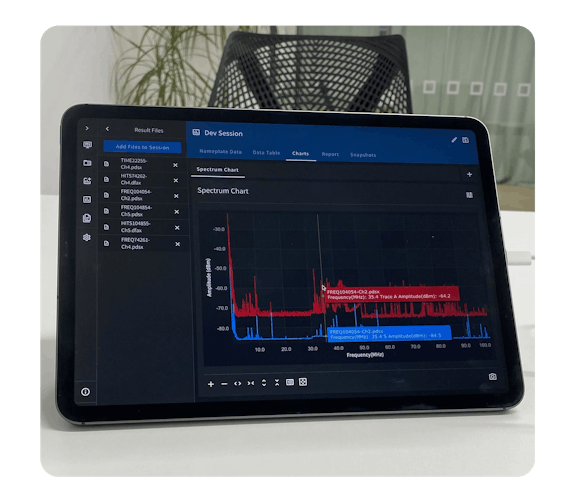

- Seamless transition between handheld field devices and desktop analysis

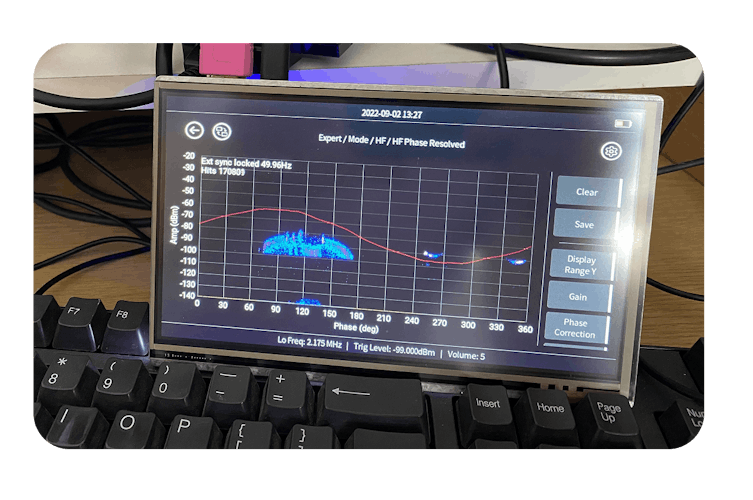

- Real-time measurement processing with 50Hz+ data streams

- Offline-first architecture ensuring zero data loss in remote locations

- Modern Material Design aesthetic optimised for industrial touchscreens

Doble Spark today

”It's always a pleasure! The Pocketworks team is probably the best, most friendly and helpful external team we've worked with in a long time, perhaps ever.

Anyone who wants a thorough discovery process leading to a top-quality UX will benefit from engaging with Pocketworks. Knowledge of your underlying technology is not essential at the beginning.”

Key facts & figures

01

Training time reduction

The time taken to onboard new engineers decreased, whilst maintaining full functionality for experienced users across all device types.

02

Field efficiency gains

Doble saw a vast improvement in field data collection efficiency through streamlined workflows and robust offline capabilities.

03

Increased user satisfaction

LEAP user satisfaction scores increased from across all age groups within six months of deployment.

04

Zero critical errors

There were no measurement errors attributed to interface confusion in the first year, maintaining the reliability critical infrastructure demands.

Take a look at the behind the scenes

Automated test sequence architecture

From manual workflows to intelligent automation

The biggest operational challenge wasn't the interface; it was workflow efficiency.

Field engineers were manually configuring and running individual electrical tests, one by one, often spending entire days on repetitive measurement sequences that could theoretically be automated.

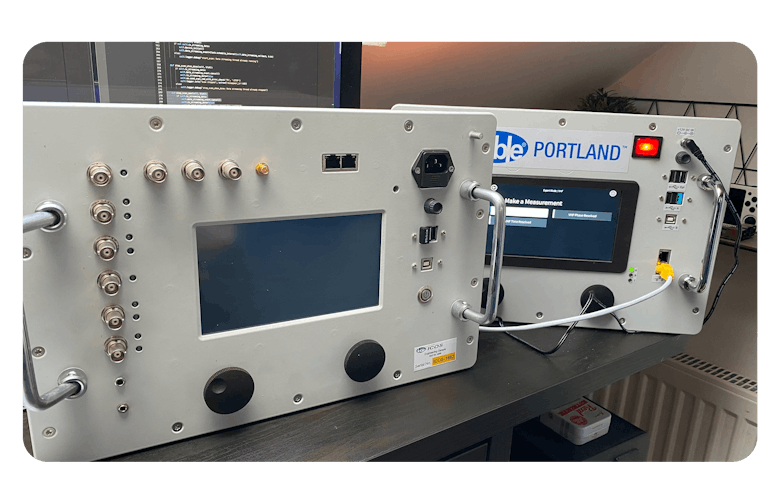

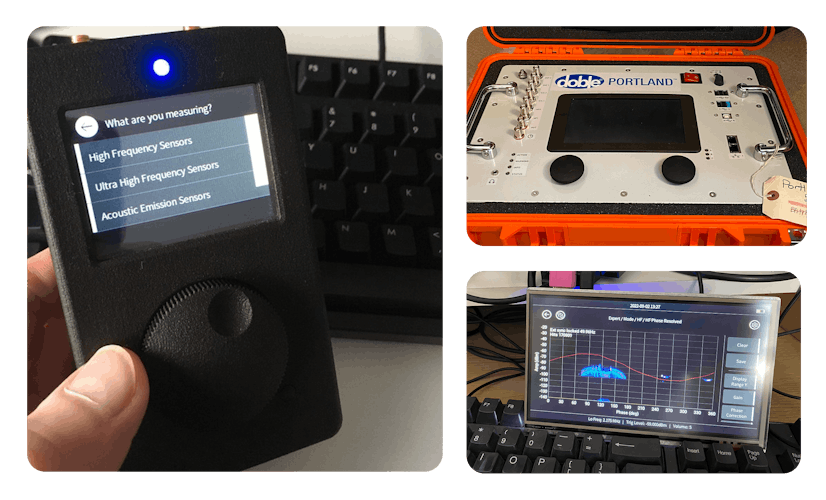

Doble wanted engineers to define comprehensive test plans that would run autonomously, but the constrained hardware presented unique challenges. With only a 7-inch touchscreen and two physical dial controls, a traditional UI-based configuration was impractical.

Our breakthrough was architectural: instead of forcing complex configuration through the limited interface, we created a human-readable JSON file format for test plans. Engineers could define intricate measurement sequences using familiar syntax, then load them onto devices.

The technical complexity lay in the execution engine. Electrical measurements ran asynchronously from the main UI thread, making it difficult to determine when one test was complete and the next could begin. We built an event-driven state machine that continuously monitored the measurement subsystem, coordinating scan progression without blocking the interface.

The elegant touch was a bidirectional capability: engineers could not only load pre-defined test plans but also "record" their manual workflows. The system would capture their actions—measurement types, parameters, timing—and automatically generate corresponding JSON files for future automation.

This transformed field work from repetitive manual tasks into strategic oversight, allowing senior engineers to focus on interpreting results rather than babysitting equipment.

Pocketworks is my first choice for any project requiring a high quality UX because I know it will be a success with the users.

Phil Boreham

Director of Engineering, Doble